23-01-2023

Table of content

Selection of Gear Lubricant Type and Additives

Choosing the Suitable Base Oil

Gear oils are essential for the smooth and efficient operation of gears and gearboxes. When it comes to selecting gear oils, several factors need to be considered to ensure optimal performance, reduced wear, and extended equipment life. In this comprehensive guide, we will delve into the key criteria for choosing the right gear oils, including viscosity, gear lubricant types, additives, and base oil selection. By understanding these factors in detail, you can make informed decisions to enhance gear performance and maximize equipment reliability.

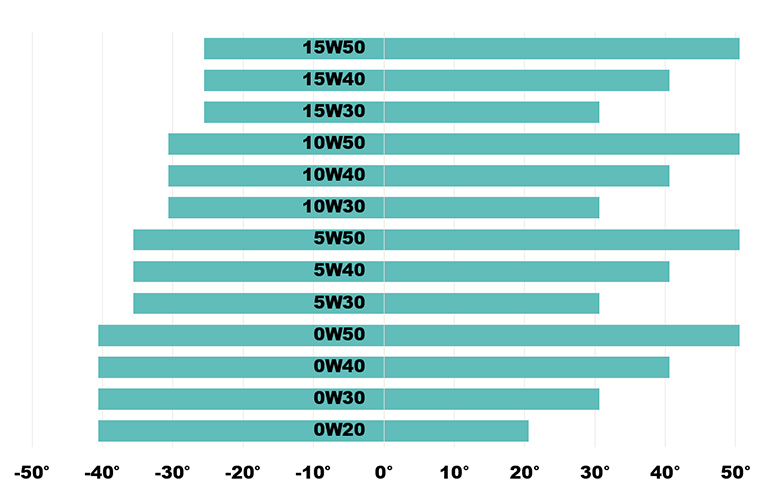

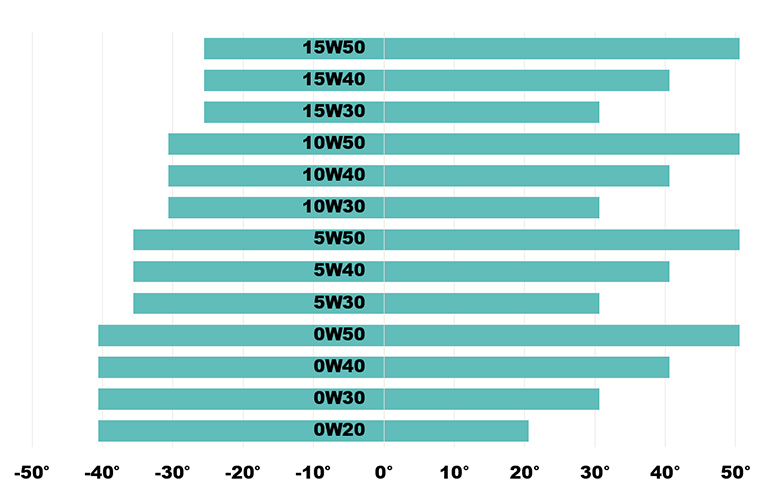

Viscosity is a critical parameter to consider when selecting gear oils. It determines the oil's resistance to flow and its ability to provide adequate lubrication under varying operating conditions. Gear oil viscosity requirements are typically specified by equipment manufacturers and depend on factors such as gear type, load, speed, and temperature. It is crucial to choose gear oils with the appropriate viscosity grade to ensure optimal lubrication and minimize wear.

Viscosity is a critical parameter to consider when selecting gear oils. It determines the oil's resistance to flow and its ability to provide adequate lubrication under varying operating conditions. Gear oil viscosity requirements are typically specified by equipment manufacturers and depend on factors such as gear type, load, speed, and temperature. It is crucial to choose gear oils with the appropriate viscosity grade to ensure optimal lubrication and minimize wear.

Find Your Gear Oil

Viscosity:

Viscosity is a critical parameter to consider when selecting gear oils. It determines the oil's resistance to flow and its ability to provide adequate lubrication under varying operating conditions. Gear oil viscosity requirements are typically specified by equipment manufacturers and depend on factors such as gear type, load, speed, and temperature. It is crucial to choose gear oils with the appropriate viscosity grade to ensure optimal lubrication and minimize wear.

Viscosity is a critical parameter to consider when selecting gear oils. It determines the oil's resistance to flow and its ability to provide adequate lubrication under varying operating conditions. Gear oil viscosity requirements are typically specified by equipment manufacturers and depend on factors such as gear type, load, speed, and temperature. It is crucial to choose gear oils with the appropriate viscosity grade to ensure optimal lubrication and minimize wear.

Selection of Gear Lubricant Type and Additives:

Different gear applications require specific gear lubricant types and additives to meet the demands of their operating conditions. Let's explore some common gear lubricant types:- R&O (Rust and Oxidation) Gear Lubricants:

R&O gear oils are versatile lubricants suitable for moderate-duty applications. They offer excellent resistance to oxidation, rust protection, and thermal stability.- Anti Scuff (Extreme Pressure) Gear Lubricants:

Anti Scuff gear oils are specifically formulated to handle high loads and extreme pressure conditions. These oils contain additives that form a protective film on gear surfaces, preventing metal-to-metal contact and reducing wear.- Compounded Gear Lubricants:

Compounded gear oils are designed for applications that require resistance to water and steam. They incorporate additives that provide excellent water separation and corrosion protection.Find Your Gear Oil

Choosing the Suitable Base Oil:

The base oil is a crucial component of gear oils and significantly influences their performance. Different base oil types are used in gear oils, including mineral oils, synthetic oils, and blends. Each base oil type has its unique properties: