PP Compound

PP Compounds are made by adding other chemicals such as inorganic fillers (like talc, mica, and glass fiber) and rubber, as well as functional additives such as flame retardants and nucleating agents, to homo, random and impact polymers. Through this, PP Compounds have greatly enhanced properties over ordinary polypropylene. There are many grades according to purposes and properties such as rigidity, conductivity, thermal resistance, glossiness, softness, paintability, and flame retardation. They are widely used in making interior and exterior materials for automotive, electric appliances' parts, and the like.

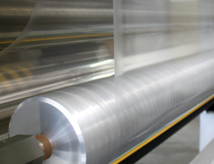

Homo Polymer

Homo polypropylene is a resin polymerized by only propylene monomers and has a fine stereoregularity, featuring a high crystallinity. It thus shows excellent rigidity and thermal resistance. Its main uses are film, yarn, and many commodity applications.

Impact Polymer

Impact polypropylene is a co-polymer of propylene and ethylene (It is polymerized differently from Random polypropylene). Impact polypropylene has not much smaller rigidity compared to the homopolymer and greatly improved impact resistance. It is used mainly in making impact-resistant materials for automotive and electronic appliances, industrial vessels, etc.

In India Gs Caltex India Pvt Ltd a 100% subsidiary of GS Caltex Korea, produces high-quality PP compound and LFT (Long Fiber Reinforced Thermoplastics) catering to various industry

LFT (Long Fiber Reinforced Thermoplastics)

LFT (long fiber reinforced thermoplastics) is a polymer composite material that is being highlighted as a metal substitute. GS Caltex manufactures twisted LFT products. Twisted LFT production technology maximizes resin impregnation into the fiber filament. This has the effect of enhancing thermal and mechanical properties. Almost all kinds of fibers can be used to produce twisted LTF. This enables the supply of products with more diverse properties to a wider range of customers.

Random Polymer

Random polypropylene is a co-polymer made by adding a small amount of ethylene in polymerizing polypropylene, which lowers molecular stereoregularity. Compared to homo polypropylene, it has structurally more atypical parts in molecular chains, so it has a little weaker rigidity. However, it has a better impact on strength and flexibility. Also, it has excellent transparency with little light scattering, compared to homo and impact polypropylene. Random polypropylene is used mainly in making transparent airtight vessels and transparent bottles, energy absorbers for autos(foam) as well as impact-resistant packaging materials.