Table of content

- Lubricating Oil: An Essential Fluid

- Characteristics of Lubricating Oil

- Categories of Lubricating Oil

- Benefits of Using Lubricating Oil

- Applications of Lubricating Oil:

- GS Caltex India: A Leading Lubricating Oil Supplier

- Choosing the Proper Lubricating Oil Manufacturer

Welcome to our comprehensive guide on lubricating oil manufacturers and suppliers. In this article, we will delve into the world of lubricating oils, their characteristics, categories, and the benefits they offer. We will also explore their various applications, with a particular focus on their use in vehicles and the importance of recycling lubricating oils. Finally, we'll provide essential tips for choosing the right lubricating oil manufacturer, featuring GS Caltex India as a leading name in the industry.

1. Lubricating Oil: An Essential Fluid

Lubricating oil, commonly known as lubricant, is a critical fluid used to reduce friction and wear between surfaces in mechanical systems. It is essential for the smooth functioning and longevity of machinery and engines. Lubricating oil acts as a protective layer between moving parts, preventing direct contact and reducing heat and energy losses.

2. Characteristics of Lubricating Oil

The effectiveness of lubricating oil depends on various characteristics:

- Viscosity: Viscosity refers to the oil's resistance to flow. Low-viscosity oils flow more easily, making them ideal for low-temperature conditions, while high-viscosity oils work well under high-temperature conditions.

- Flash Point: The flash point is the temperature at which oil vapors ignite when exposed to an open flame. A higher flash point indicates better safety and stability under high-temperature conditions.

- Pour Point: This is the lowest temperature at which oil ceases to flow. Oils with low pour points perform better in cold environments.

- Additives: Lubricating oils may contain additives to enhance specific properties, such as anti-wear, anti-foam, and corrosion resistance.

3. Categories of Lubricating Oil

There are various types of lubricating oils tailored for specific applications:

- Mineral Oils: These are the most common lubricants derived from crude oil refining. They offer good lubrication properties and are cost-effective.

- Synthetic Oils: Synthetic lubricants are chemically engineered and provide superior performance, stability, and longevity, making them ideal for high-stress applications.

- Bio-Based Oils: These lubricants are made from renewable resources and are environmentally friendly, offering a sustainable alternative to traditional oils.

4.Benefits of Using Lubricating Oil

Using quality lubricating oils from reputable manufacturers provides several advantages:

- Reduced Friction and Wear: Lubricating oil minimizes friction and wear between moving parts, reducing the likelihood of breakdowns and extending the lifespan of machinery.

- Improved Efficiency: Proper lubrication results in improved energy efficiency, leading to reduced fuel consumption in vehicles and lower operating costs in industrial settings.

- Heat Dissipation: Lubricating oil helps dissipate heat generated during operation, preventing overheating and potential damage to the machinery.

- Corrosion Protection: Many lubricating oils contain additives that protect surfaces from corrosion and rust, ensuring longer equipment life

5.Applications of Lubricating Oil

Lubricating oils find applications in various industries and settings:

a)Use in Vehicles:

- Automotive: Lubricants play a vital role in vehicles, ensuring smooth engine operation, reducing fuel consumption, and extending engine life.

- Industrial Machinery: In manufacturing plants and industrial settings, lubricating oils are used in heavy machinery to enhance performance and reduce maintenance requirements.

b)Recycling:

Recycling used lubricating oil is crucial for environmental sustainability. Improper disposal of used oil can lead to soil and water contamination. Re-refining and reprocessing used lubricating oil can give it a new life, reducing the need for virgin oil and conserving resources.

6. GS Caltex India: A Leading Lubricating Oil Supplier

GS Caltex India is a prominent name in the lubricant industry, offering a wide range of high-quality lubricating oils. As a subsidiary of GS Caltex Corporation, a global energy and petrochemical company, GS Caltex India upholds the highest standards of product quality, innovation, and environmental responsibility.

- Product Range: GS Caltex India provides a comprehensive range of lubricating oils, including mineral oils, synthetic oils, and specialty products designed to meet diverse industrial needs.

- Sustainability: GS Caltex India is committed to sustainability and eco-friendly practices. They actively promote used oil recycling and environmental awareness, contributing to a greener future.

- Technical Support: The company offers technical support and guidance to customers, ensuring the right lubrication solutions for their specific applications.

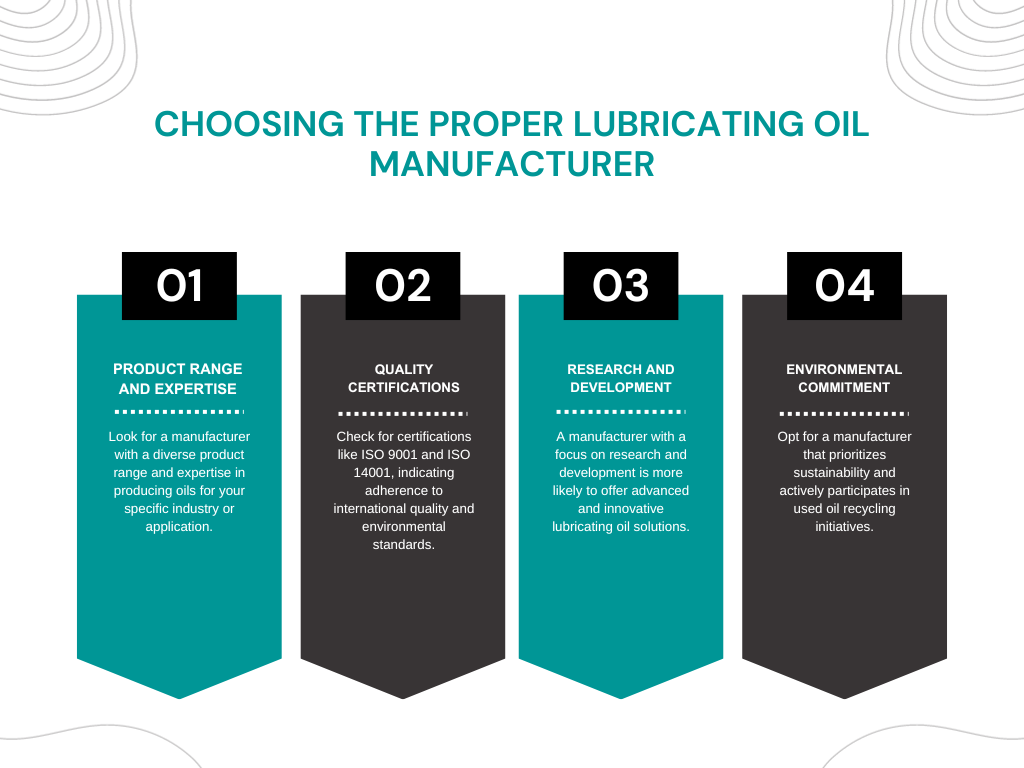

7. Choosing the Proper Lubricating Oil Manufacturer

Selecting the right lubricating oil manufacturer is crucial for ensuring product quality and performance. Consider the following factors when making your decision:

- Product Range and Expertise: Look for a manufacturer with a diverse product range and expertise in producing oils for your specific industry or application.

- Quality Certifications: Check for certifications like ISO 9001 and ISO 14001, indicating adherence to international quality and environmental standards.

- Research and Development: A manufacturer with a focus on research and development is more likely to offer advanced and innovative lubricating oil solutions.

- Environmental Commitment: Opt for a manufacturer that prioritizes sustainability and actively participates in used oil recycling initiatives.

Conclusion

Lubricating oil is a fundamental component in the smooth operation and longevity of machinery and engines. Choosing the right lubricating oil manufacturer, such as GS Caltex India, ensures the use of high-quality products with a commitment to environmental sustainability. By understanding the characteristics, categories, and benefits of lubricating oils, as well as their various applications and importance in recycling, individuals and industries can make informed decisions to enhance performance and reduce their ecological footprint.