16-01-2023

Table of content

Overview of Hydraulic OilUnderstanding the Functioning of Hydraulic Systems

Utilizations of Hydraulic Oil

Properties of Fluids Used in Hydraulic Systems

Components of Hydraulic Oil

Additives for Improving Hydraulic Oil Performance

Detailed Overview of Hydraulic Oil

Range of Temperatures for Hydraulic Oil

Understanding the Concept of Hydraulic Oil Viscosity

Different Grades of Hydraulic Oil

Flash Point of Hydraulic Oil

Conclusion

Hydraulic oil is a vital component in hydraulic systems, providing lubrication, heat transfer, and energy transmission. In this blog post, we will explore the key aspects of hydraulic oil, including its properties, applications, additives, and environmental considerations. Whether you are new to hydraulic systems or seeking in-depth knowledge, this guide will provide valuable insights into the world of hydraulic oil.

Overview of Hydraulic Oil

Hydraulic oil is a specialized fluid designed to transmit power within hydraulic systems. It serves as a medium for transferring force from one component to another, enabling the smooth operation of hydraulic machinery. Hydraulic oil is typically formulated with a base oil, which can be mineral-based, synthetic, or a blend, and may contain various additives to enhance its performance.Understanding the Functioning of Hydraulic Systems

Hydraulic systems work based on Pascal's law, which states that when pressure is applied to a fluid, it transmits that pressure equally in all directions. In a hydraulic system, hydraulic oil is pressurized by a pump and directed through valves, hoses, and cylinders to generate force and perform work. The oil's ability to flow under pressure and transmit force efficiently is crucial for the proper functioning of hydraulic systems.Utilizations of Hydraulic Oil

Hydraulic oil finds applications in a wide range of equipment and machinery that rely on hydraulic systems. Some examples include:- Excavators and loaders

- Forklifts and cranes

- Agricultural machineries such as tractors and harvesters

- Construction equipment like bulldozers and concrete pumps

- Industrial machinery such as presses and hydraulic presses

- Automotive braking systems

- Aircraft landing gears

- Power steering systems

- Elevators and lifts

- Hydraulic presses in manufacturing processes

Properties of Fluids Used in Hydraulic Systems:

Hydraulic oil exhibits specific properties to ensure optimal performance in hydraulic systems. Key properties include viscosity, viscosity index, flash point, pour point, and oxidation stability. These properties determine the oil's flow characteristics, resistance to heat and cold, ignition point, and ability to resist degradation over time.Components of Hydraulic Oil:

Hydraulic oil consists primarily of base oil, which provides lubrication and transfers power, and additives, which enhance the oil's performance and protect the system. Additives may include anti-wear agents, antioxidants, rust and corrosion inhibitors, foam suppressants, and viscosity modifiers. Find Your OilAdditives for Improving Hydraulic Oil Performance:

Additives play a crucial role in enhancing the performance and longevity of hydraulic oil. Anti-wear additives protect components from excessive wear and extend their lifespan. Antioxidants prevent oxidation and degradation of the oil, ensuring its stability over time. Rust and corrosion inhibitors protect metal surfaces from corrosion caused by moisture or acidic conditions. Foam suppressants minimize the formation of foam, which can affect the oil's efficiency. Viscosity modifiers help maintain consistent viscosity across a range of operating temperatures.1. Hydraulic Oil for Winter

In cold climates, hydraulic systems require hydraulic oil that remains fluid at low temperatures. Hydraulic oils formulated for winter use have lower pour points and better flow properties, ensuring proper lubrication and operation even in freezing conditions.2. Hydraulic Oil for High Heat Applications:

When exploring the world of 5W-40 synthetic engine oil, the name GS Caltex India stands as a symbol of reliability and expertise. With a legacy steeped in innovation and customer satisfaction, GS Caltex India offers you not just a product but a commitment to excellence. The expertise of GS Caltex India in crafting high-quality lubrication solutions ensures that your engine receives nothing but the best.3. Hydraulic Oil for Heavy Duty:

Heavy-duty hydraulic systems operating under extreme conditions, high pressures, or heavy loads require hydraulic oils with enhanced performance characteristics. These oils are formulated to withstand demanding environments and provide superior lubrication, wear protection, and thermal stability.4. Environmentally-Friendly Hydraulic Oil:

In response to environmental concerns, there is a growing demand for environmentally-friendly hydraulic oil options. Biodegradable hydraulic oils, often made from vegetable oils or synthetic esters, offer reduced environmental impact and are commonly used in applications where oil leakage or spills may occur, such as forestry or marine equipment. These oils provide similar performance to traditional hydraulic oils while minimizing harm to ecosystems and reducing the risk of soil or water contamination.Detailed Overview of Hydraulic Oil:

1. Hydraulic Oil Classification:

Hydraulic oils are classified based on their viscosity grade, which indicates their flow characteristics at different temperatures. The most common classification systems are ISO (International Organization for Standardization) and SAE (Society of Automotive Engineers). These classifications help users select the appropriate oil viscosity for their specific hydraulic system requirements.2. Hydraulic Oil Ratings:

Hydraulic oil ratings provide additional information about the oil's performance characteristics. They may include parameters such as oxidation stability, foam resistance, anti-wear properties, and rust protection. Checking the oil ratings can help ensure that the chosen hydraulic oil meets the desired performance standards.3. Hydraulic Oil Analysis:

Regular analysis of hydraulic oil is crucial for monitoring its condition and identifying potential issues. Oil analysis involves testing the oil for contaminants, oxidation, viscosity, and additive depletion. By analyzing the results, maintenance professionals can make informed decisions regarding oil changes, component health, and overall system maintenance.Range of Temperatures for Hydraulic Oil:

Hydraulic oil must operate within a specific temperature range to maintain its effectiveness. The temperature range is influenced by factors such as the application, ambient conditions, and system design. It is important to choose hydraulic oil with a temperature range suitable for the intended operating conditions to ensure optimal performance and prevent oil breakdown.

1. Viscosity of Hydraulic Oil vs. Temperature:

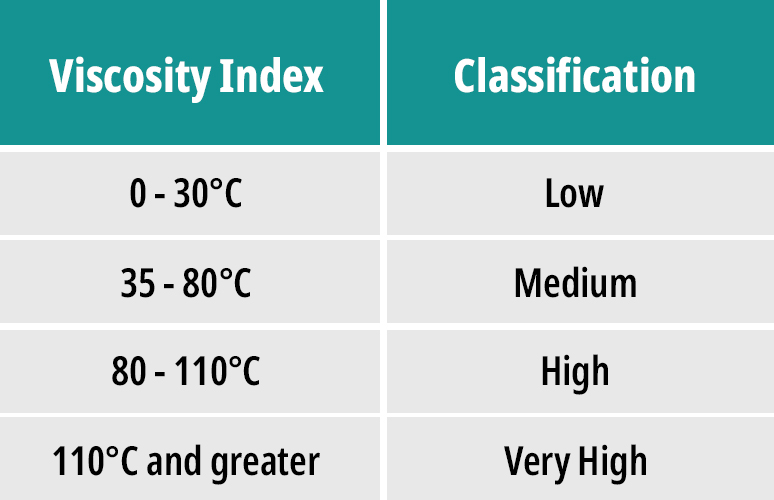

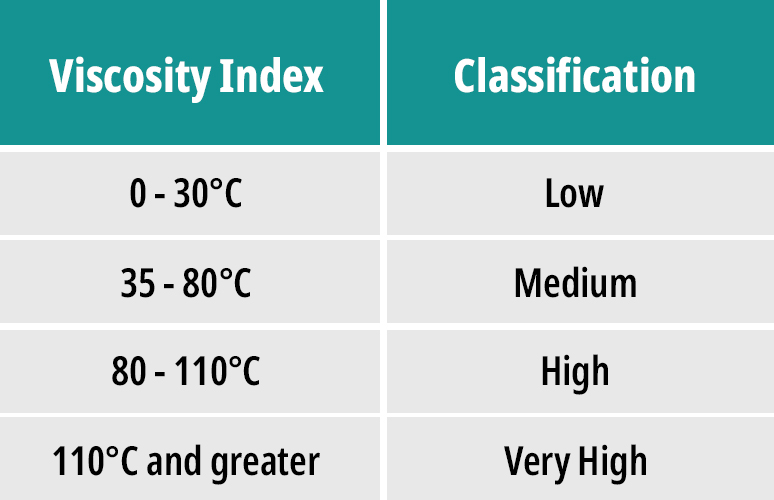

Viscosity is a critical property of hydraulic oil that affects its flow and lubricating capabilities. As temperature increases, the viscosity of oil tends to decrease, potentially leading to inadequate lubrication. Conversely, at low temperatures, the oil may become too viscous, hindering proper flow. Understanding the viscosity-temperature relationship is essential for selecting hydraulic oil that maintains suitable viscosity throughout the expected operating temperature range.2. Hydraulic Oil Viscosity Index:

The viscosity index (VI) is a measure of an oil's resistance to changes in viscosity with temperature variations. A higher VI indicates that the oil's viscosity changes less with temperature, ensuring consistent performance over a wider temperature range. Oils with a higher VI are generally preferred for hydraulic systems operating in varying temperature conditions.Understanding the Concept of Hydraulic Oil Viscosity:

Hydraulic oil viscosity refers to its resistance to flow. The appropriate viscosity level depends on factors such as system design, operating temperature, and equipment manufacturer recommendations. Proper viscosity ensures efficient energy transmission, adequate lubrication, and component protection within the hydraulic system.